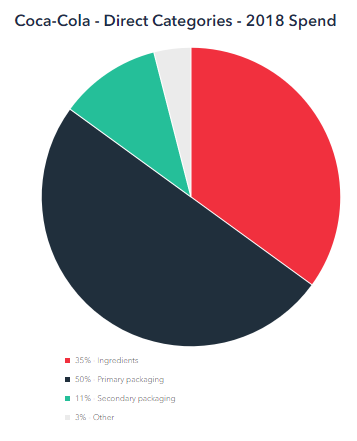

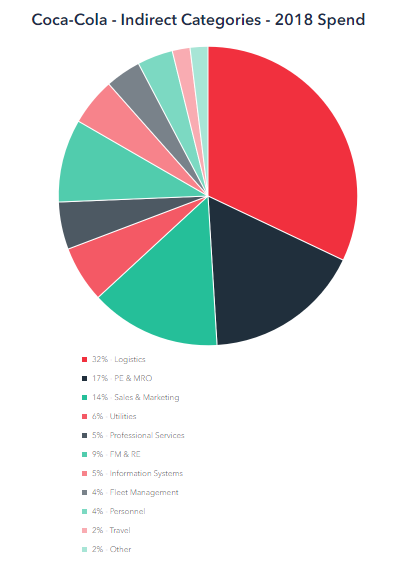

We place significant focus on forming partnerships with suppliers that have supply points located within our countries, both multinational and local while also developing strong local suppliers across our territories. These efforts support our strategy for local sourcing and contributing to socioeconomic development in the countries where we conduct business. These suppliers significantly contribute to our business and include key markets such as Russia, Nigeria, Italy, Romania and Poland. Coca‑Cola HBC annual spend with suppliers in 2018 reached 3.24 billion euro and 4.89 billion euro including concentrates, cold drink equipment and traded goods. Our practice is to source locally, provided that goods and services are available to meet our requirements and quality standards in an economically viable way.

Over 95% of our spending is local in our countries of operation or from within the European Union, which is considered local for EU countries

Engaging with our suppliers.

We work with our suppliers to build a responsible and sustainable supply chain.

We partner with our suppliers to provide new technologies for equipment, packaging, cold drink equipment, vending machines and with our logistics providers to minimize our impact and environmental footprint, and improve our performance. Given the diversity of countries from which we source, we are aware that the labor, human rights and ethical business practices of our suppliers reflect on the reputation of the Coca‑Cola System.

At Coca‑Cola HBC, we are committed to high standards of performance related to human rights, labor practices, minimizing environmental impact, ensuring health and safety, ethical business and unsurpassed quality in our supply chain. Our supplier partners play a critical role in ensuring that we deliver against these standards.

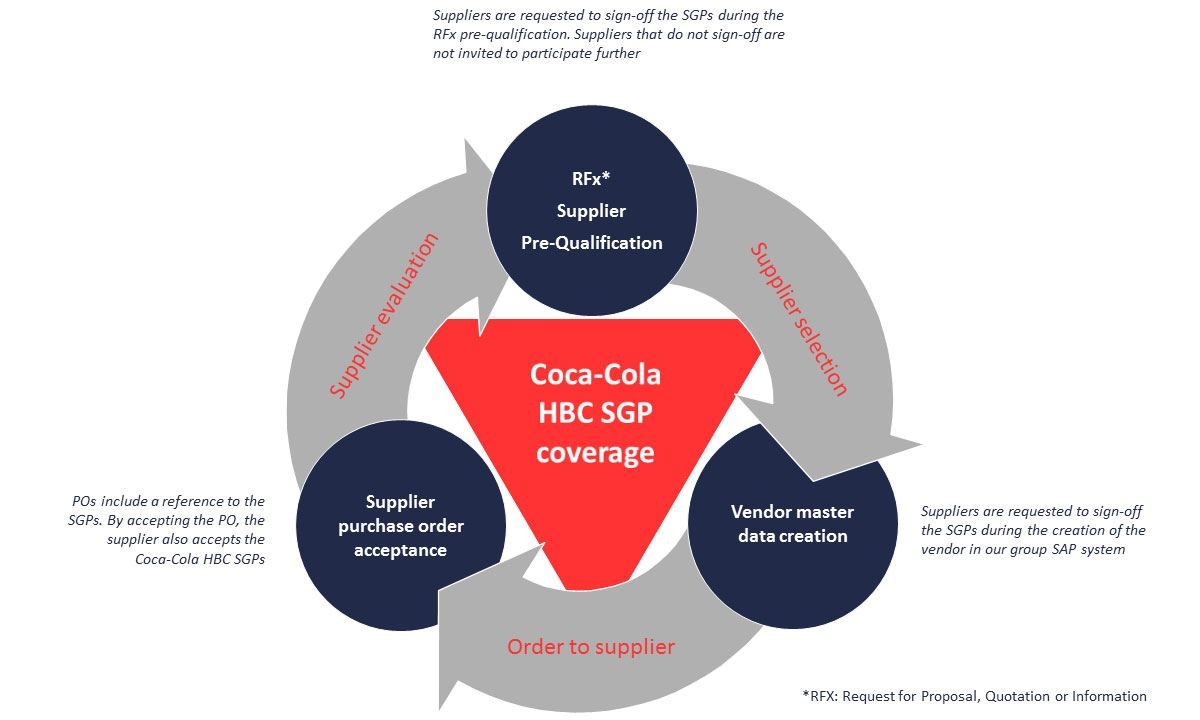

To ensure proper governance and that our suppliers meet our standards, we have implemented policies including our Coca‑Cola HBC Supplier Guiding Principles (SGP) and Coca‑Cola HBC Sustainable Agriculture Guiding Principles (SAGP). In addition, we have developed an environmental, social and governance supplier pre-assessment process for our strategic buy segment which includes criteria for supplier selection. We monitor compliance of our critical suppliers by utilizing The Coca‑Cola Company Supplier Guiding Principles compliance audits and EcoVadis CSR Platform. We also recognize supplier certifications as per international standards including ISO 9001, 14001, 50001, FSSC 2200 and OHSAS 18001. For agricultural commodities, we recognize the Rain Forest Alliance, Fairtrade International, Bonsucro, Sustainable Agriculture Initiative Platform (SAI Platform), GlobalG.A.P. & GRASP certifications.

"By following our Supplier Guiding Principles, our suppliers are expected to comply as a minimum with applicable environment and local labor laws and core international conventions. We work collaboratively with our suppliers on the journey to meet the expectations of our customers and consumers and enable sustainable mutual growth." Yannis Leousis, Chief Procurement Officer

Adhering to our SGPs involves, at a minimum, complying with applicable environment and labor laws and core international conventions. These principles also communicate our values, and our expectations for responsible business practices.

We aim to achieve 100% of our suppliers accepting our SGPs by utilizing our ‘SGP Coverage Triangle’ with three checkpoints throughout the Procure-To-Pay process: